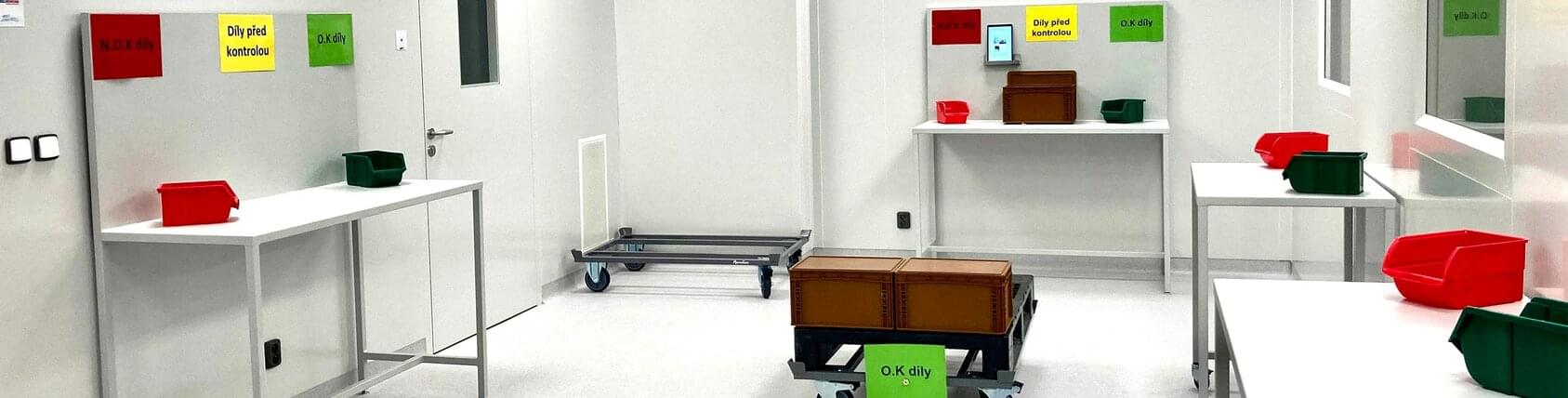

We have recently added quality control in so-called clean rooms. By using this control we increase safety,

functionality, reliability, lifespan and quality of your products. Thanks to the inspection process, we reduce the failure rate caused by contamination of the external environment. By combining these factors, you will reduce the cost of manufacturing your products.

Visual inspection of components in

the cleanest environment possible

A technically clean environment will move your production to perfection.

We minimize contamination of components

We increase the quality of your products

We reduce your costs

Video tour

See what it looks like at our facilities

Facilities + ESD box

Laminar box

Presentation of our facilities

Important for you and for us

What we emphasize here

Industry

- Automotive

- Medical

- Electrical Engineering

- Mechanical Engineering

Standard

- VDA 19.1, VDA 19.2

- ISO 16232

- ISO 13485

- ISO 14644

Values

- Reliability

- Functionality

- Safety

- Lifespan

Consultations and training

Audits

Visual inspection

System and process setting

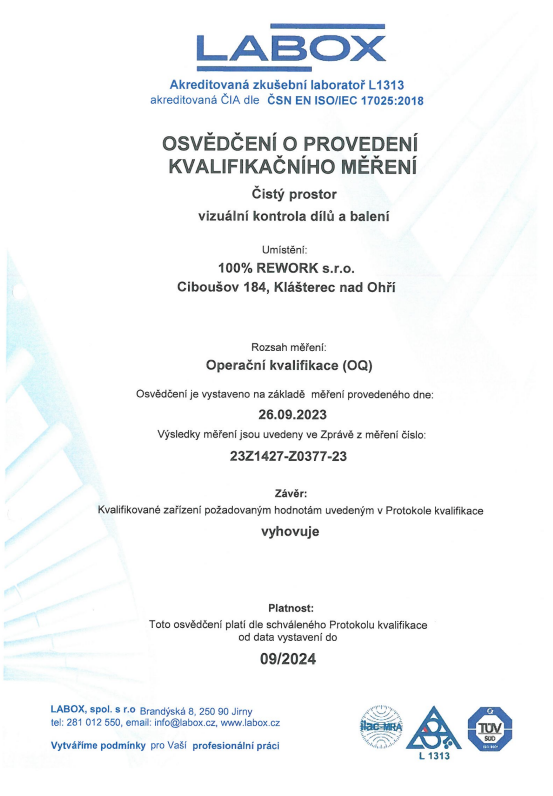

V našich čistých prostorech dosahujeme vynikajících výsledků

Podle Kvalifikačního měření třídy čistoty dle ČSN EN ISO 14644-1:2019 naše prostory vyhovují normě ISO 7.

Tabulku s oficiálními výsledky Kvalifikačního měření naleznete ZDE

Cooperation without any risk

We evaluate risks for you

1

We meet the standards

We have evaluated all risks in accordance with the ČSN EN ISO 9001:2016 standard. We meet customer requirements in the area of automotive, especially IATF 16949 and VDA standards.

2

Regular audits

We have got trained VDA 6.3 process auditors who regularly perform internal audits of all our workplaces.

3

Corrective measures

In case of discrepancies, we set corrective measures for which we use the PDCA methodology, 8D report, Ishikawa diagram and others.

Cooperation

Our cooperation step by step

Step 1

Contact us

Get in touch with us or leave us a contact. We will get back to you as soon as possible to arrange a meeting.

Step 2

Your needs and requirements

Prepare documents and specific requirements for our meeting.

Step 3

Solution proposal

We will tailor a solution to your specific requirements.

Step 4

We will sign the contract

We will sign all the necessary documents and set a date for the work to commence.

Step 5

We start our cooperation

There is nothing to stop the cooperation now. Thanks to the online status of your order, we will stay in touch at all times.